YOUR IMPACT | MORE ABOUT IPP & PRS

Have

you ever wondered

at the supermarket how all these products

get there?

European projects make IPP & PRS a truly international place to work

Our closed pooling systems

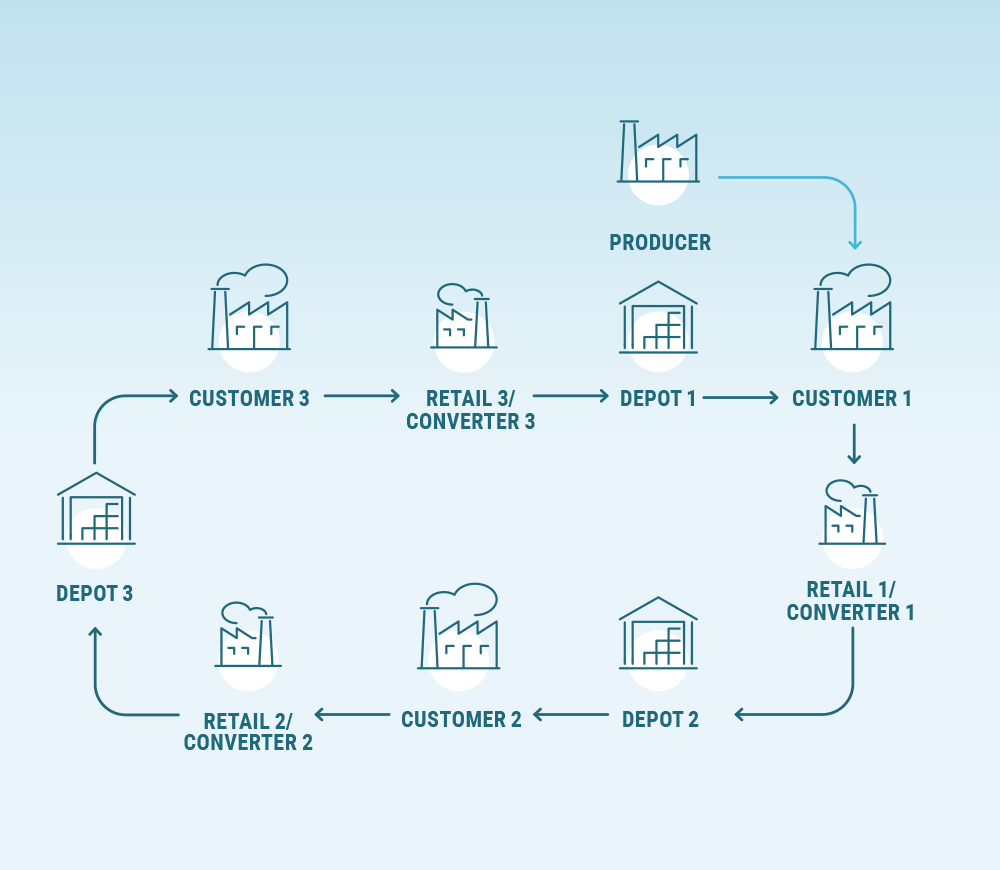

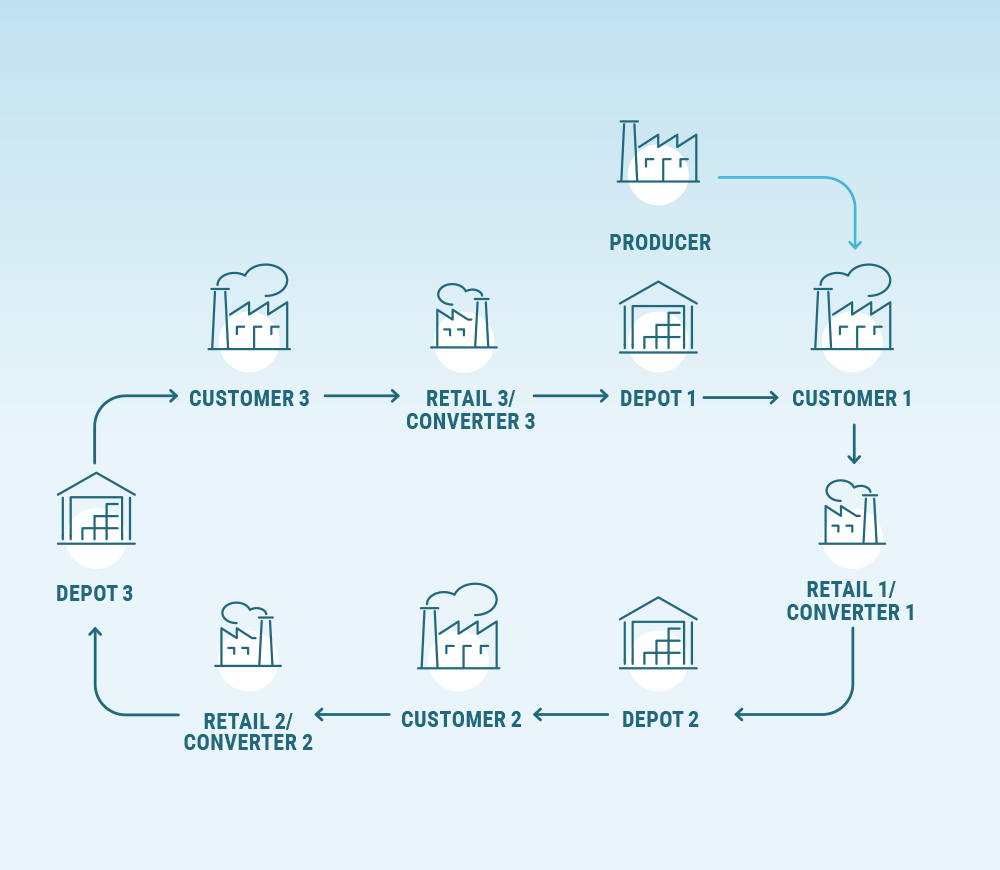

Closed pooling is a system for reuse in which reusable load carriers are circulated by IPP & PRS without change of ownership, meaning that IPP & PRS remain remains owner of the load carriers.

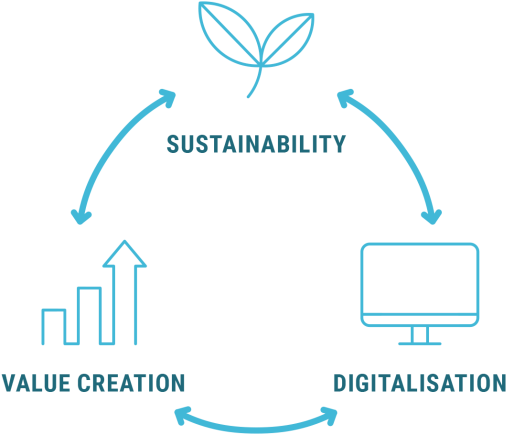

Business Strategy faber group

With 400 employees, we operate a circular reuse system

The very nature of what we do is a natural circular model of pooling

Each business unit consists of Commercial and Operational teams, supported by functions like Finance, Human Resources, IT and Marketing & Communications. The European headquarters ensures alignment, harmonisation and efficiencies between all business units to ensure we operate as a European logistics provider in the most sustainable and efficient way possible. Most functions also have communities in which we share best practices and work together across markets on European projects – which makes IPP & PRS a really international place to work.

The European headquarters of IPP & PRS , which also houses the Benelux business unit of IPP, is located in Eindhoven in the Netherlands. Our other business units and locations are:

Germany-Austria-Switzerland (Ennepetal, Germany)

France (Angers, France)

Iberia (Madrid, Spain)

Poland (Warsaw, Poland)

United Kingdom & Ireland (Coventry, UK)

At IPP & PRS our 400 employees work every day to see that the load carrier needs of our customers are fulfilled in the best way possible. According to our customers, IPP & PRS stand out for their quality and service. We work to high standards, go the extra mile and are easy to work with.

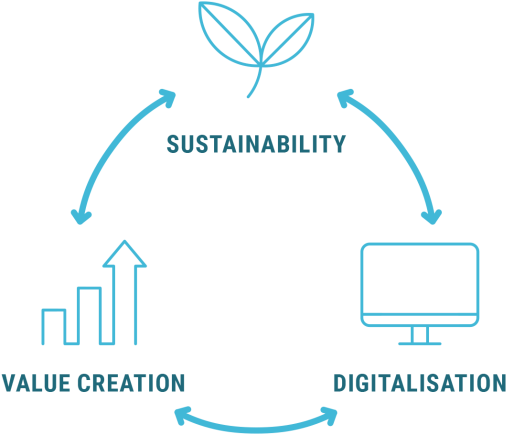

Next to sustainability, digitalisation is a core element of our business strategy. Digitalisation enables us to optimise the logistic process around our pallet pool, as well as keep track of our assets. Together with Connected Load Carrier, we are currently deploying pallets fitted with a tracking device. This way we can reduce pallet loss, which reduces replacement costs while, at the same time, increasing our sustainability performance. But this is just the start: in a next stage we can provide customers with data to optimise their supply chain, and offer additional services, like tracking temperature and humidity, and shock detection of the pallet and its load, which can be important for food or valuable products.

In this regard we focus on the areas where we can make most impact: reducing the footprint of our logistics operations, optimising the lifecycle of our load carriers, and doing this in partnership with all stakeholders throughout our supply chains. For example, we have received two-star European Lean & Green recognition.

Lean & Green is a leading programme to optimise transport routing & loading, avoid empty returns and reduce fuel consumption. To optimise the lifecycle of our pallets we have programmes in place to repair pallets to the max instead of scrapping them. We also use any salvageable material from pallets that have reached the end of their useful service life instead of using new timber – all of course up to our high-quality standards.

To make customers and retailers more aware of the importance of pool pallets not straying ‘out-of-network’ or becoming lost, IPP launched a campaign to increase the recovery rate. This benefits the efficiency of the supply chains IPP supports while fulfilling its own sustainability ambition to reduce the company’s footprint. The success of a sustainable and efficient pool depends on making sure pallets stay in the network and are used in an optimal way. When pallets become unavailable – because they are being held, unused, as overstock in a warehouse or, even worse, because their whereabouts is unknown due to poor data management – this jeopardises the efficiency and sustainability of the pooling system.

At PRS, we have a similar initiative with PRS Green Label. The polymer granulate is transported by our customers -usually in big bags on PRS pallets- to plastic product producers, called ‘converters’. With the Green Label we recognize converters who ensure a high return percentage of our pallets to PRS.

IPP & PRS are member of Faber Group, an international family run company specialised in circular load carrier services. Our pallet pool consists of over 18 million load carriers that make over 85 million trips per year. By providing our pool pallets and boxes on a pay-per-use basis we ensure that our pallets are used in an optimal way. And as owner of the load carrier, IPP & PRS ensure that they are kept in good condition throughout their lifespan so that pallets can last for years. IPP & PRS work with over 180 depots and selected hauliers throughout Europe to ensure efficient and sustainable shipment of load carriers, storage and, if needed, repairs. For our customers, pay-per-use means that they don’t have the hassle of ownership or need to invest in load-carriers. So they can fully focus on their core business.

IPP & PRS are pallet pooler, a vital part of supply chains. With around 400 employees, we operate a circular reuse system for high quality pallets & boxes throughout Europe. We have over 1,750 customers, representing many well-known brands, producers and retailers. All kinds of goods travel on our pallets - from consumer goods such as coffee, dairy, cereals and personal hygiene products at IPP to polymer granulate at PRS for the plastic converting industry.

International place to work

All over Europe

Around 400 employees

Digitalisation

Sustainable impact

18 million load carriers

Vital part of supply chains

Welcome to IPP & PRS. We are a member of the Faber Group and specialise in the pooling of load carriers. Did you know that almost every product you have at home once travelled on a pallet? Pallets are indispensable load carriers for supply chains to transport goods in a safe, efficient, standardised way from factory and warehouse all the way to retail stores.

Closed pooling is a system for reuse in which reusable load carriers are circulated by IPP & PRS without change of ownership, meaning that IPP & PRS remain remains owner of the load carriers.

Around 400 employees

Each business unit consists of Commercial and Operational teams, supported by functions like Finance, Human Resources, IT and Marketing & Communications. The European headquarters ensures alignment, harmonisation and efficiencies between all business units to ensure we operate as a European logistics provider in the most sustainable and efficient way possible. Most functions also have communities in which we share best practices and work together across markets on European projects – which makes IPP & PRS a really international place to work.

International place to work

European projects make IPP & PRS a truly international place to work

The European headquarters of IPP & PRS , which also houses the Benelux business unit of IPP, is located in Eindhoven in the Netherlands. Our other business units and locations are:

Germany-Austria-Switzerland (Ennepetal, Germany)

France (Angers, France)

Iberia (Madrid, Spain)

Poland (Warsaw, Poland)

United Kingdom & Ireland (Coventry, UK)

All over Europe

At IPP & PRS our 400 employees work every day to see that the load carrier needs of our customers are fulfilled in the best way possible. According to our customers, IPP & PRS stand out for their quality and service. We work to high standards, go the extra mile and are easy to work with.

Our closed pooling systems

With 400 employees, we operate a circular reuse system

Business Strategy faber group

Next to sustainability, digitalisation is a core element of our business strategy. Digitalisation enables us to optimise the logistic process around our pallet pool, as well as keep track of our assets. Together with Connected Load Carrier, we are currently deploying pallets fitted with a tracking device. This way we can reduce pallet loss, which reduces replacement costs while, at the same time, increasing our sustainability performance. But this is just the start: in a next stage we can provide customers with data to optimise their supply chain, and offer additional services, like tracking temperature and humidity, and shock detection of the pallet and its load, which can be important for food or valuable products.

Digitalisation

In this regard we focus on the areas where we can make most impact: reducing the footprint of our logistics operations, optimising the lifecycle of our load carriers, and doing this in partnership with all stakeholders throughout our supply chains. For example, we have received two-star European Lean & Green recognition.

Lean & Green is a leading programme to optimise transport routing & loading, avoid empty returns and reduce fuel consumption. To optimise the lifecycle of our pallets we have programmes in place to repair pallets to the max instead of scrapping them. We also use any salvageable material from pallets that have reached the end of their useful service life instead of using new timber – all of course up to our high-quality standards.

To make customers and retailers more aware of the importance of pool pallets not straying ‘out-of-network’ or becoming lost, IPP launched a campaign to increase the recovery rate. This benefits the efficiency of the supply chains IPP supports while fulfilling its own sustainability ambition to reduce the company’s footprint. The success of a sustainable and efficient pool depends on making sure pallets stay in the network and are used in an optimal way. When pallets become unavailable – because they are being held, unused, as overstock in a warehouse or, even worse, because their whereabouts is unknown due to poor data management – this jeopardises the efficiency and sustainability of the pooling system.

At PRS, we have a similar initiative with PRS Green Label. The polymer granulate is transported by our customers -usually in big bags on PRS pallets- to plastic product producers, called ‘converters’. With the Green Label we recognize converters who ensure a high return percentage of our pallets to PRS.

Sustainable impact

The very nature of what we do is a natural circular model of pooling

IPP & PRS are member of Faber Group, an international family run company specialised in circular load carrier services. Our pallet pool consists of over 18 million load carriers that make over 85 million trips per year. By providing our pool pallets and boxes on a pay-per-use basis we ensure that our pallets are used in an optimal way. And as owner of the load carrier, IPP & PRS ensure that they are kept in good condition throughout their lifespan so that pallets can last for years. IPP & PRS work with over 180 depots and selected hauliers throughout Europe to ensure efficient and sustainable shipment of load carriers, storage and, if needed, repairs. For our customers, pay-per-use means that they don’t have the hassle of ownership or need to invest in load-carriers. So they can fully focus on their core business.

18 million load carriers

IPP & PRS are pallet pooler, a vital part of supply chains. With around 400 employees, we operate a circular reuse system for high quality pallets & boxes throughout Europe. We have over 1,750 customers, representing many well-known brands, producers and retailers. All kinds of goods travel on our pallets - from consumer goods such as coffee, dairy, cereals and personal hygiene products at IPP to polymer granulate at PRS for the plastic converting industry.

Vital part of supply chains

Welcome to IPP & PRS. We are a member of the Faber Group and specialise in the pooling of load carriers. Did you know that almost every product you have at home once travelled on a pallet? Pallets are indispensable load carriers for supply chains to transport goods in a safe, efficient, standardised way from factory and warehouse all the way to retail stores.